Grizzly Island Slough

| Grizzly Island Slough |

|

Bill George, Premier Industries, Sacramento, CA |

|

|

Problem |

|

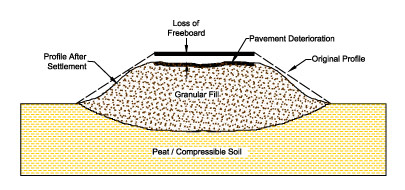

Raised levees at Grizzly Island Slough built on marshy soil settled over time. Adding more fill (weight) to bring the levee to original grade resulted in additional settlement over the years. |

|

|

|

|

The California Department of Water Resources wanted to find a permanent solution. Over the years they had considered various types of lightweight materials, but none had the desired properties. |

|

Implementation |

|

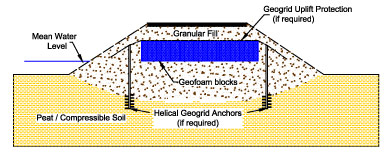

The Design team decided to construct 5 test sections ranging in length from 100' to 400' using EPS geofoam. A three foot thickness of the existing levee was removed. Excavated material was stockpiled and then reused as fill. The approximate width of levee at crown was 12'. Side slopes on both levee shoulders are 1V:2H. With addition of EPS geofoam, the the levee elevation was increased by 0.5 feet compared to the original. The dimensions of the geofoam fill were 2'(depth) by 10'(width). A total of 952 cubic yards of geofoam was used. |

|

|

|

After the selected levee sections were excavated, geotextile was placed on the exposed subgrade. A 6-inch leveling course of granular soil was placed over geotextile. The geofoam blocks were placed on the leveling course. A geomembrane was placed over the geofoam fill. The membrane extended two feet beyond the sides of the blocks and rested directly on the 6-inch leveling course. A geotextile fabric was placed over the geomembrane as added protection. The excavated levee material was placed and compacted over the geofoam fill to bring the top of the levee to the desired elevation. The final lift, or cap, consisted of a granular base. |

|

The project started in mid July and was completed in 4 weeks. |

|