Geofoam Research Center

| Design and Construction |

|

|

| Load Distribution |

|

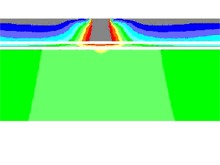

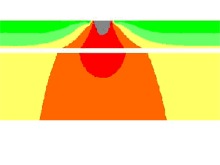

Geofoam punctures easily. Therefore, direct application of concentrated loads is undesirable. In most applications, plain or reinforced concrete slab is formed over the final top surface for load distribution and protection. Alternatively, adequate soil cover can be provided to reduce stress intensities at the geofoam surface. The following figures show conceptual stress distributions in an EPS geofoam fill with and without a load distribution slab. |

|

| Chemical Degradation |

|

EPS geofoam dissolves in the presence of liquid petroleum products and organic compounds. Although the probability of a tanker spill on an EPS geofoam fill is extremely small, safeguards may be incorporated into the embankment design. These safeguards may include providing a concrete slab to direct spilled petroleum away from the geofoam blocks, or placing an impervious (to petroleum) geomembrane above the geofoam blocks. In situations where the surrounding soil has been contaminated and contains organic fluids, geofoam blocks can be encapsulated within plastic sheeting. When geomembranes are used for this purpose, the interface shear strength between the geomembrane and the geofoam and between the geofoam and the overlying soil should be adequate to resist the design loadings. Alternatively, geofoam blocks affected by the spill could be quickly replaced and the road re-paved in the area of the spill. |

|

|

|

A petroleum tanker spill is an environmental hazard and the entire area would likely require environmental remediation if such an event were to occur. On large projects, the additional cost for protecting geofoam blocks against petroleum and organic compounds should be compared to the potential cost of remedial construction. |

|

|

| Flammability |

|

Regular geofoam is combustible and protecting against fire hazard is an important consideration. Stockpiles of geofoam or placed blocks can catch fire and measures to mitigate fire hazard should be adapted. Geofoam intended for large volume stockpiling and applications may be specified to contain flame retardant additives. Provision of sand fire wall between large geofoam clusters has been utilized to further reduce fire hazard. Even with flame retardant additives, storage and handling of geofoam blocks should be done with attention to fire safety. |

|

|

| Ultraviolet Radiation |

|

Subjecting EPS geofoam to ultraviolet radiation results in surface deterioration. Research at GRC indicates there is no detrimental change in interface friction caused by UV degradation over 3 months exposure to sunlight and also on samples subjected to accelerated weathering in the laboratory. Pressure washing of a UV degraded geofoam surface re-establishes adhesion bonding and maximum interface strength. |

|

|

| Insects |

|

Insects may nest in geofoam placed underground. Geofoam portions installed in close proximity to wood structural elements have in rare cases been found to be infested by termites. Some manufacturers can produce geofoam with a proprietary insect control additive. Other than in cases related to subsurface home insulation, there have been no known instances of insect infestation problems in lightweight fill applications over more than 25 years anywhere around the world. Geofoam has no nutritional value. Insects either bore through or use geofoam for habitation. This problem is very rare and only tends to occur only in warm climate of the Southern States and where there is a food source. |

|

|

| Buoyancy |

|

The very low densities of geofoam (much lower than water) imply that considerable uplift forces can result due to buoyancy when submerged. Adequate surcharge must be provided or ground water levels must be controlled to ensure stability against uplift both during construction and while in service. For some applications, consideration of uplift resistance anchors may be a viable alternative. |

|

|

| Water Adsorption |

|

Geofoam tends to absorb a small amount of water over time. Moisture enters the closed cellular structure by diffusion of water vapor and subsequently condenses. Some water is also absorbed in the space between fused cellular elements. The amount absorbed depends on the type of geofoam, density and duration of exposure to moisture. Field observations indicate EPS can absorb up to 1 percent per year in volume. This level of moisture absorption does not compromise the desired low density feature nor adversely affect the strength and deformation properties of geofoam. A higher density is used in design to account for future change in weight due to moisture absorption. Some degradation in thermal properties occur with moisture absorption. |

|

|

| See also... |

|

|

| Differential Icing |

|

Geofoam below pavements will tend to impede frost penetration and upward flow of ground heat. Pavements constructed over geofoam may in some circumstances become icy while adjacent pavements without geofoam remain ice free. Such differential icing conditions can also occur between normal grade supported pavements and bridge decks. A vehicle traveling on an ice-free road may encounter a sudden change to icy conditions during differential icing. The extent of differential icing on traveled roadways can be minimized by increasing the granular base thickness for pavement structures over geofoam. |

|

|

| Design Life |

|

The physical properties and stress-strain behavior of EPS geofoam remain relatively well preserved with time. Samples retrieved from a geofoam fill after a 24 years did not show evidence of degradation. Past experience to date suggests that satisfactory performance of geofoam over the design life of most projects can be expected. |

|

|

|

|