By Gregory Reuter,

P.E, P.G, Consulting Geotechnical Engineer

and Engineering

Geologist, GME Consultants, Inc., Minneapolis, Minnesota.

Introduction

A segment of County Trunk Highway "A", located within a remote region of Bayfield County

in northern Wisconsin, required continued patching and maintenance of the pavement due to the

presence of a slow-moving, creep landslide. The problem persisted for over 20 years until it

was decided that remedial work be performed in order to stabilize the landslide movement.

Location of Bayfield County, Wisconsin

Landslide Description

The landslide caused subsidence and cracking within an approximately 45 m wide section of

highway embankment. The highway embankment was originally constructed over a ravine formed

by a nearby creek, with the creek being diverted through a culvert beneath the embankment.

Geologically, the area is overlain by glacio-lacustrine soils deposited during the final

retreat of the Wisconsinan glacial ice sheet, within high water stages of what is presently

Lake Superior. These soils generally consist of very soft, highly plastic clays and silts.

The thickness of these water-lain soils is estimated to be over 50 m at the project site.

The failure occurred within the approximately 14 degree side slope of the embankment fill.

The elevational height between the head of the slide and the toe was about 5 m. Well-defined

tensile and lateral shear cracks within the asphalt pavement of the highway had developed along the head of the

slide, even though the bituminous wear course through this area was frequently patched.

The geotechnical exploration included the measurement of piezometric levels, and the measurement

of deep-seated movement through the installation of an inclinometer within the body of the

landslide. Sufficient creep movement was measured over the few weeks following

installation of this instrumentation to help define the location of the subsurface failure

plane. This allowed for the reconstruction of the slide geometry needed for the

back-calculation of the residual shear strength along the surface of sliding.

Remedial Design

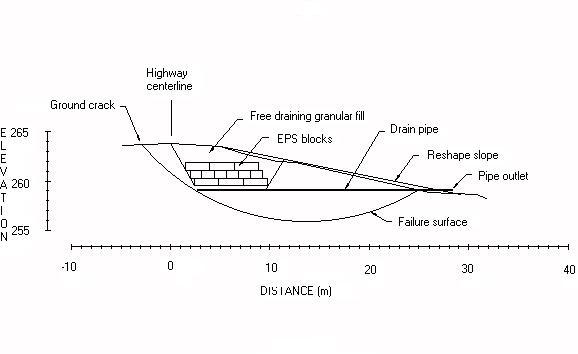

The failure surface was found to occur at a depth of 6.1 m below grade at the location of

the inclinometer casing. At first glance, a simple alternative for stabilization would

seem have been to completely excavate all of the soil within the slide mass and replace

it with compacted granular fill; however, this approach would have meant temporarily closing

the highway, which is a main thorough-fare for the local residents. In addition, the

excavation would have extended below the water table in order to reach the deep sliding

surface, requiring extensive groundwater control and surface water diversion of the creek.

To reduce the driving moment of the slide, it was decided to partly excavate the embankment

fill from within the head of the slide and replace it with lightweight polystyrene geofoam,

as shown in the following figure.

Generalized cross-section showing geofoam placement

Differential Icing

Due to the insulating effects of geofoam, an important consideration when using geofoam

beneath pavements, particularly in northern climates, is the potential development of

differential icing on the pavement surface. This is defined as the formation of ice on the

surface of an insulated pavement when the adjacent, non-insulated pavement is free of ice.

Unlike bridge deck icing, which can be anticipated by motorists, differential icing along a

normal stretch of highway cannot be anticipated, and therefore can pose a serious safety

problem. The intent is not to eliminate icing, but to attempt to time the formation, and

degree of severity, of ice formation to be nearly compatible with icing over non-insulated

areas (Horvath, 1995). Therefore, the top of the geofoam was embedded at a depth of 1.5 m

below final pavement grade, which is consistent with the anticipated frost depth in the

Bayfield County area.

Construction

Buoyancy is also a concern with geofoam. Prior to placing the geofoam blocks, a drainage

blanket and leveling pad were constructed at the base of the excavation, consisting of a

0.3 m thick layer of free-draining sand. Within this drainage layer a 200 mm diameter

slotted plastic pipe was placed parallel to the road

centerline at the back of the excavation. Additional perforated drain lines were installed

extending out perpendicular from the centerline pipe at regular intervals, which

daylighted the final embankment face.

The thickness and location of the geofoam installation were determined through a series of

stability analyses in order to achieve a post-construction factor of safety of 1.5 with

respect to global stability. Based on the results of these analyses, three layers of geofoam

blocks were placed on top of the drainage blanket, with each layer stair-stepped upward and

into the embankment. Each of the layers extended out perpendicular from the road

centerline and were orientated such that each successive layer was placed with the long axis

of the blocks perpendicular to the previous layer. The blocks were shipped to

the site by tractor-trailer truck; however, no special equipment was required for unloading

and placing the blocks since each block was light enough to be handled manually.

Field placement of the geofoam

The backfill surrounding and overlying the block layers consisted of compacted free-draining

sand. To reduce the potential for deterioration by petroleum infiltration from possible

spills or leaks from the highway vehicular traffic, the geofoam was covered with an

impermeable sheeting prior to placing the final fill over the top of the geofoam blocks.

Conclusion

A number of considerations must be reviewed in deciding an appropriate remedial measure for

landslide stabilization. The use of lightweight geofoam provides a viable solution

particularly where the reduction of the landslide driving force is required without

permanently lowering the grade at the head of the slide. The use of lightweight EPS

geofoam on the CTH "A" project allowed for a rapid construction process, which reduced the

amount of over-all excavation required, and minimized the impact of construction on the

continued use of the highway. The work was completed during the summer of 1999, and

the slope has performed satisfactorily since its remediation.

References

Horvath, J.S., Geofoam Geosynthetic, Horvath Engineering P.C., 1995

Negussey, D., "Properties & Applications of Geofoam," Society of the Plastics

Industry, Inc., 1997

Reuter, G.R., and Rutz, J., "A Lightweight Solution for Landslide Stabilization,"

Geotechnical Fabrics Report, Vol. 18, No. 7, September, 2000, p. 42-43

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|