NA-00 Creep of Small Geofoam Samples

| Creep Test on Geofoam (2-inch cubic samples) - NA |

|

|

|

|

Creep tests were carried out for geofoam samples of different densities from four different manufacturers. Geofoam samples of two inch cube were loaded with constant loads that gives stress of 30%, 50% and 80% of the strength at 5% strain and the creep behavior was observed. The relationship between the vertical strain and the creep time for the above stress levels are given in graphical form. It is found that a stress level of 80% of the strength of the geofoam of given density produces as large strain as 50 % except for Knauf Basf geofoam blocks. The stress levels of 50% and 30 % of the strength produce strains lesser than 3 % and 2% percent respectively with in 30 days of loading. For Knauf Basf geofoam blocks it was found that the sample reaches its 40% strain at a constant load of 80% of the strength just in 15 hours whereas the strain at stress level of 30% strength was found to be less than 2% in 30 days. This indicates that in cases where the live loads on geofoam may become dead loads, the design load should be below 30% of the strength of the geofoam to avoid failure due to excessive settlement over a long period of time. |

|

|

| Creep behavior of 2 and 2.5 inch Geofoam Samples - Sri |

|

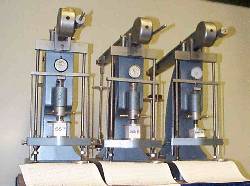

Geofoam exhibit creep deformation at constant stress levels which are well below the compression strength. Therefore the creep behavior of geofoam play major role in most application of Geofoam. Creep tests were performed for 2 and 2.5 inch EPS Geofoam samples from four manufactures on Creep testing machine. 2 and 2.5 inch cubes were loaded to 30,50 and 80 percent compressive strength on creep testing machine and axial deformations were recorded with time. The compressive strength was taken as stress at 5 percent strain in unconfined compression. The results show that the creep strain at 50 percent compressive strength is less than three percent and it remains moreover constant after three days. The creep strain at 80 percent compressive strength is higher than 20 percent even at 24hours and it keeps on increasing with time. 2.5 inch samples indicate less axial strain than 2inch sample at 80 percent strength and therefore the creep deformation at constant stress levels depend on the sample size. This trend was not well observed at 30 and 50 percent strength because of the seating error. |

|

|

| Creep behavior of 4 inch Geofoam Samples - Sri |

|

Geofoam exhibit creep deformation at constant stress levels which are well below the compression strength. Therefore the creep behavior of geofoam play major role in most application of Geofoam. Creep tests were performed for 4 inch EPS Geofoam samples from four manufactures on MTS. Samples were loaded to 30,50 and 80 percent compressive strength on creep testing machine. Axial deformations and axial loads were recorded with time. The compressive strength was taken as stress at 5 percent strain in unconfined compression. The results show that the creep strain at 50 percent compressive strength is less than 0.015 and it remains moreover constant after three days. The creep strain at 80 percent compressive strength is higher than 0.15 even at 24hours and it keeps on increasing with time. 4 inch samples indicate less axial strain than 2 and 2.5 inch sample at 30,50 and 80 percent strength and therefore the creep deformation at constant stress levels depend on the sample size. |

|

|

|

|

|