Geofoam Research Center

|

Creep

|

|

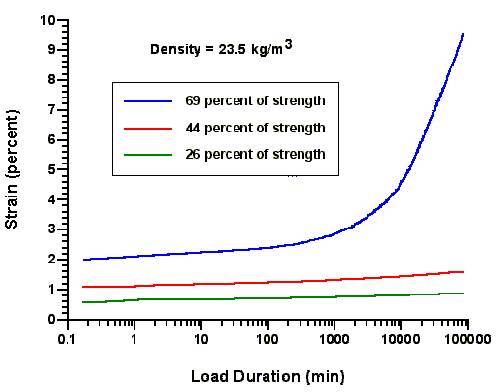

Geofoams exhibit creep deformation under sustained stress levels well below specified compressive strength. The results of creep tests at different stress levels on geofoam samples of the same density are shown below. |

|

|

These stresses represent 69, 44 and 26 percent of the 121 kPa compression strength at 5 percent strain for the nominal density of the specimens. Each test result is extrapolated backwards to intercept the strain axis. The initial or immediate strains obtained in this manner are 2.0, 1.1 and 0.6 percent for load levels at 83, 53 and 32 kPa, respectively. It should be noted that each specimen was initially subjected to a seating stress of 0.7 kPa for 24 hours before applying the corresponding sustained load. This was done to minimize the previously described initial seating error related deformations. In addition to the initial strains and after eight weeks of loading, the accumulated creep strains are 7.5, 1.6 and 0.3 percent, respectively. |

|

Other data (BASF 1993) indicate creep related strain magnitudes remain reasonably small for stress levels that produce an initial strain of 1.5 percent or less. The stress level that produces 1.5 percent initial strain increases with geofoam density. |

|

|

|

References |

|

|

|

BASF Corporation (1993). Styropor Foam as a Lightweight Construction Material for Road Base-Courses. Styropor Technical Information TI 1-800 e 24558 June 1991/Sept 1993 |

|

Negussey, D., Jahanandish, M., (1993). A Comparison of Some Engineering Properties of EPS to Soils. |

|

|